White Sand Usage Tips For Cost-Effective Construction

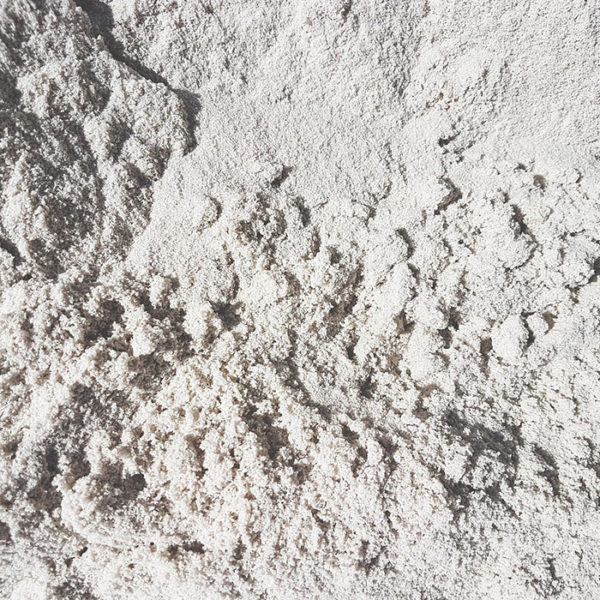

On September 29, 2025 by adminWhite sand is a fundamental building material, prized for its purity and consistency. Its role in creating strong, durable, and aesthetically pleasing structures is well-known. However, using it intelligently can lead to substantial savings without compromising on quality.

By focusing on smart sourcing and application, builders can significantly improve a project’s financial efficiency.

Smart sourcing and procurement:

The cost of white sand is heavily influenced by transportation. Procuring material from the nearest reliable supplier minimizes freight expenses. Builders should compare quotes from multiple local quarries, considering the delivered price per unit rather than just the base rate. Bulk purchasing for the entire project phase often secures a better overall price compared to small, frequent orders.

Sand grading:

Not all construction activities demand the same grade of white sand. Using a premium, fine-grade sand for applications like plastering is appropriate for a smooth finish. For concrete work or masonry mortar, a well-graded, coarser sand is perfectly suitable and often less expensive. Specifying the right grade for each task prevents paying a premium for quality where it is not functionally necessary.

Efficient on-site management:

Proper on-site storage is a simple way to avoid waste. Sand should be placed on a solid, level platform and covered with tarpaulins to protect it from wind and rain. This prevents loss from scattering and maintains the sand’s ideal moisture content, ensuring consistent mix quality and avoiding the necessity to order replacement material due to spoilage.

Optimized mix design:

A precise, laboratory-tested mix design ensures every kilogram of white sand is used effectively. An accurately proportioned mix with the correct sand-to-cement ratio achieves the design strength without over-engineering. This eliminates the use of excess material, directly reducing the amount of sand and cement consumed in every batch of concrete or mortar.

Reducing waste in application:

Training the workforce on best practices minimizes spillage and overuse. Techniques like using measured gauging boxes for batching instead of makeshift shovels ensure proportion accuracy. For plastering, applying the correct thickness avoids using extra material. A conscious effort to reduce on-site waste translates to lower material orders.

Exploring alternatives for specific uses:

In certain non-structural applications, alternatives to white sand can be considered. For example, filling under floors or in trenches might effectively use a different, locally available material that is less costly. This reserves the higher-quality white sand for plastering and concrete work where its properties are most valuable, optimizing the overall material budget.

Archives

Calendar

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| 27 | 28 | 29 | 30 | 31 | ||